The Use of Mycelium Bio-Composites for Environmentally Sustainable Insulation

Mark Velichko1

1Bristol Grammar School, Bristol, England

Youth STEM Matters, no. 3 (2025); https://doi.org/10.51892/ysm.3.202501M. Velichko, "The Use of Mycelium Bio-Composites for Environmentally Sustainable Insulation," Youth STEM Matters, no. 3, 2025.

If you cite this article or use it in any academic activities please let us know by e-mailing us at editor@youthstem2030.org.

Abstract

Introduction

Thermal insulation refers to highly thermally resistant materials that can decrease the heat flow rate, thus keeping the heat or cool within a building and preventing heat flux with the surroundings. Effective insulation conserves energy, reducing the use of natural resources for power generation, and lowering greenhouse gas (GHG) emissions [1]. In fact, the burning of fossil fuels to heat poorly insulated buildings is a major issue, with 87 Mt CO2e being released as a result in the UK in 2019, accounting for 17% of the country’s GHG emissions [2].

Commercially available insulation materials used in construction include fiberglass, mineral wool and expanded polystyrene. These materials can be efficiently produced at a large scale, are highly durable and lightweight, and maintain their thermal insulation properties for a long period [3]; expanded polystyrene, for instance, can last 30-50 years [4]. Expanded polystyrene is the most popular insulating material: the expanded polystyrene sector is anticipated to maintain the largest building thermal insulation market share between 2023 and 2032 [5]. However, these materials have several problems, namely the long time required to decompose, health hazards and their unsustainable manufacturing process. For example, expanded polystyrene, which is made from styrene monomers obtained from petroleum, can take billions of years to degrade naturally [6]. Moreover, styrene is also reasonably anticipated to be a human carcinogen, and workers exposed to it have had a greater mortality rate from cancer of the lymphohematopoietic system [7]. Apart from being made from unsustainable and toxic materials, the manufacturing process often involves the release of harmful greenhouse gases, including hydrofluorocarbons [8], which are damaging to the ozone layer. The US Environmental Protection Agency gives hydrofluorocarbons a global warming potential — a measure of how much energy one ton of a gas will absorb over a given time, relative to one ton of carbon dioxide— of up to 12,400 (for 100 years), compared to one for carbon dioxide, 28 for methane and 265 for nitrous oxide [9]. This shows that the gases involved in the polystyrene manufacturing process present a significant threat to climate. Therefore, there is an urgent need to find more sustainable types of insulation, one of which can be fungi, such as Pleurotus ostreatus and Pleurotus eryngii, which were used in this investigation [10].

For many people the first thing that comes to mind when thinking about fungi is the image of a mushroom. However, mushrooms are only the fruit bodies of a fungus: they produce spores to reproduce, much like apples on a tree. The actual “tree”, the vegetative part of a fungus which creates the fruit bodies, is called mycelium. Mycelium is usually invisible, buried in its substrate, and consists of a dense mat of branching, thread-like filaments called hyphae, through which nutrients, cytoplasm and genetic information travel [10,11]. The mycelium grows apically (from its tip or apex) and during this process the fungus does not create a chain of individual, walled–off cells, but rather adds to existing tissue, extending a single, massive, interconnected cell [11].

One of the most important properties of mycelium is that it acts as an adhesive agent, binding its substrate together to form a dense block [12]. Basidiomycetes fungi, such as the ones used in this investigation, can rapidly digest lignin – an organic polymer that forms one of the chief constituents of wood – changing their structure into lignin-based radicals, which can act as adhesives. The cellulose, also found in the substrate, can be converted into chitin – a polysaccharide found in fungal cell walls – using enzymes. The chitin provides the most strength and support to the hyphae, allowing them to push through multiple layers of substrate as they grow, which can weigh several pounds [13]. Mycelium and mycelium bio-composites have also been found to be waterproof, fireproof, and contain anti-microbial properties [14-16]. The thermal conductivity of mycelium has been reported to range between 0.05 and 0.07 W/mK, which portrays adequate properties of heat insulation and is similar to the values obtained in this study [10, 14, 17, 18]. These qualities have been recognised in the packaging and textiles industry, where mycelium bio-composites are starting to be manufactured and used commercially [19].

Another type of insulation material with similar properties which is currently in use is wood fibre insulation. The two materials are alike in containing wood pulp which is bound together, and they also have similar manufacturing procedures. Therefore, it is useful to compare the different stages of both processes to highlight the benefits of mycelium bio-composites and draw a direct comparison of the various stages of manufacturing of mycelium insulation, partially based on the procedure used in this investigation, to that of wood fibre insulation (Table 1).

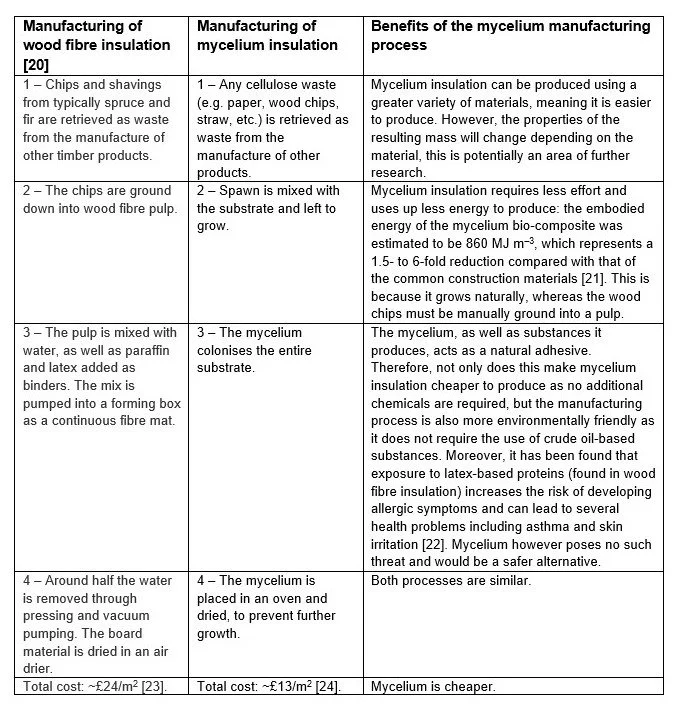

Table 1 – A comparison of manufacturing wood fibre and mycelium insulation. Benefits of mycelium manufacturing are highlighted.

The production of mycelium insulation is indicated as cheaper and easier, requiring less manpower and practically no complex machinery. Mycelium production is also environmentally friendly: it contains no toxic chemicals and breaks down easily once it is no longer needed. This makes it different to other alternatives such as wood fibre insulation, polystyrene and mineral wool, all of which are more difficult to produce and cannot be disposed of easily since the plastic microparticles within the materials do not decompose well.

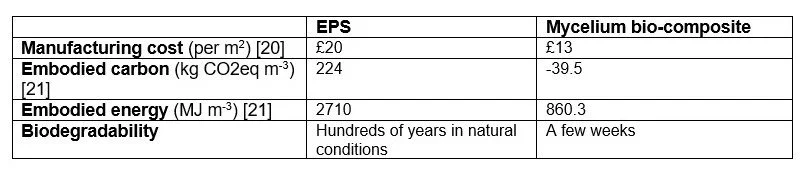

The types of fungi used in this investigation, P. ostreatus and P. eryngii, are both classified as basidiomycetes, which are widespread and easy to grow. Two types of expanded polystyrene – EPS and EPS70, which has a greater compressive strength and higher thermal conductivity than EPS – were chosen as a conventional material, as they are widely used worldwide [5]. EPS is manufactured by expanding polystyrene beads into foam at high temperatures, using pentane or carbon dioxide. During this process the product is filled with pockets of air, which give it its insulative properties [20]. It is difficult to compare the two manufacturing processes directly – as was done with wood fibre insulation — due to significant differences in the ways they are produced. However, a simple comparison of cost, embodied carbon (an estimate of the contribution to climate change made by the production of a product) and embodied energy (the total energy used to manufacture a material) of each material can be made (Table 2).

Table 2 – A comparison of EPS and mycelium bio-composite production. Cost, embodied energy, embodied carbon and biodegradability are compared.

This comparison conveys that mycelium requires less energy and costs less to manufacture, and the negative embodied carbon value suggests that it absorbs carbon, unlike EPS which has a positive value.

The thermal insulation properties of a material can be characterised by several heat transfer factors: thermal conductivity, heat capacity and thermal diffusivity, which are necessary to measure to allow for a comparison of the materials [20].

Thermal Conductivity

Thermal conductivity measures the ease with which heat can travel through a material. It is defined by the amount of heat energy transferred between two layers of a material with a temperature difference equal to one degree Celsius in 1 second. Mathematically, the heat conduction is described by Fourier’s law:

where P is energy power, Tin is inside temperature, Tout is outside temperature, h is the material’s thickness, A is surface area and k is the thermal conductivity (measured in W/mK).

Having a low conductivity of container walls means that less energy is required to maintain a constant temperature inside the container.

Heat Capacity

Heat capacity (thermal capacity) is defined as the amount of heat to be supplied to an object to produce a unit change in its temperature and characterises the heat absorption properties of a material.

Thermal Diffusivity

Thermal diffusivity is the ability of a material to conduct thermal energy relative to its heat capacity. It is defined as

where α is thermal diffusivity, k is thermal conductivity, c is specific heat capacity (heat capacity of 1 kg of a material) and ρ is density of material (calculated by dividing the mass of an object by its volume). If the temperature distribution inside a material is non-uniform, then the heat will be transferred from hotter areas to the colder areas in order to produce an even distribution of heat. The time taken for the temperature to distribute is characterised by the thermal diffusivity of the material, which is a measure of the material’s thermal buffering properties.

Low thermal diffusivity is an important feature of insulation, especially in areas with a hot climate. For example, the walls of a stone house have a higher conductivity than that of polystyrene. This means that it will require more energy to maintain a constant temperature (provided the outside temperature is cooler) than a polystyrene container. However, the thermal diffusivity of the stone walls will be lower than that of polystyrene, meaning that it will take longer for the temperature of the air inside a stone house to increase, compared to the air in a polystyrene container, if it is hot outside. This means that in places with a hot climate, the air inside a stone house will remain cool, whereas the air inside a polystyrene container will heat up quickly. The heat in the stone walls will gradually be released when temperatures drop during the night [25].

To accurately measure heat transfer factors, specialised equipment and a controlled experimental set-up (to prevent all possible energy leaks) were required. This equipment and set-up were not available to use for this investigation. Therefore, a different approach with a simplified apparatus was taken. A container was made from each material, and the air inside was heated and cooled. The time taken for the container to heat and cool, as well as the energy necessary to maintain a constant temperature, were recorded. These experiments allowed for an approximate estimation and comparison of the heat transfer factors of the different test materials. This investigation aims to test the thermal insulation properties of mycelium insulation made from P. ostreatus and P. eryngii mycelium, compared to those of commercially available products, EPS and EPS70E. The results of initial experiments reported in this paper indicate that mycelium shows optimal thermal insulation properties, with thermal diffusivity two to three times lower than EPS, allowing a preliminary conclusion on the effectiveness of mycelium bio-composites as insulation to be drawn.

Methods

Production of Mycelium Bio-Composite

First, to successfully produce numerous mycelial bricks, it is important to develop a method to grow the fungi efficiently, with maximum output and minimum effort or expense, and in the correct quantities. The mycelium used in this investigation was grown by mixing 300g of fungal spawn with 500g of hydrated oak pellets as substrate which had been pasteurised in boiling water for 1 hour (Fig. 1(a)) to remove contaminants and increase the chances of successful colonisation by the fungus. After the spawn had been mixed with the substrate, it was left to grow at room temperature in a dark location, simulating the darkness of its natural environment, and was sprayed with water three times a day. Each fungus took approximately 10 days to fully colonise the substrate (Fig. 1(b) and 1(c)). After 10 days, the fungus began fruiting (Fig. 1(d-f)), signalling that colonisation was complete. Oak pellets were chosen as a substrate as they provide basic nutrients necessary for fungal growth and generally do not support the growth of contaminants before hydration, as the high temperatures involved in making the pellets kill and remove any contaminants. This made the pasteurisation process easier as there were fewer contaminants to start with. Whilst adding nutritional supplements to the substrate, such as flour, would have benefited the fungus, it would have been harder to avoid contamination and more rigorous sterilisation would have been necessary, so this was avoided [26]. A large dose of mushroom spawn (300g) was mixed in to compensate for the limited availability of nutrients in this substrate (compared to other substrates), so fast colonisation of the substrate could still take place.

Figure 1 – Growing of mycelium: (a) Day 1. Fungal spawn is mixed with the substrate. (b) Day 6. The mycelium begins to colonise the substrate. (c) Day 9. The substrate is fully colonised. (d-f) Days 10 – 14. The mycelium begins to produce mushrooms.

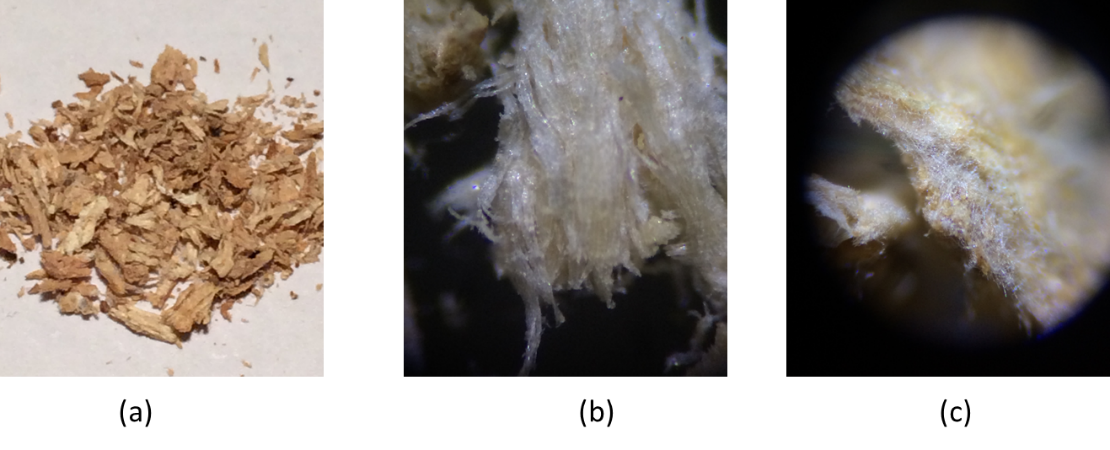

Mycelium may be barely visible to the naked eye (Fig. 2(a)), but a closer look under a microscope (Fig. 2(b) and 2(c)) revealed that microscopic mycelium fibres had intertwined with wood fibres in the wooden chips, meaning that mycelium made up a significant volume fraction of the final product.

Figure 2 – Wood chips colonised by mycelium. (a) Mycelium composite material (mycelium fibres are not visible by the naked eye). (b-c) Optical microscope images showing mycelium fibres covering wooden chips (10x magnification).

After the colonisation was complete, the mycelium composite was baked for 1 hour at 90°C. The baking was essential to stop further growth by killing the mycelium and removing moisture, leaving behind a firm product. After baking, the mycelium block (Fig. 3(a) and 3(b)) was cut up into 2cm thick slices (Fig. 3(c)), ready to be glued together using PVA to form a container. Containers were made in two different configurations: configuration 1, with inside dimensions 5x4.5x11 cm; and configuration 2, with inside dimensions 8x4x13 cm. To compare the thermal insulation properties of mycelium and traditionally used materials, additional containers were manufactured using EPS (Fig. 4(a)) in configurations 1 and 2, and EPS70E (Fig. 4(b)) in configuration 2. The P. ostreatus and P. eryngii containers (Fig. 4(c) and 4(d)) were made in configurations 1 and 2 respectively. The two configurations were randomly chosen based on the amount of material available and should not affect the heat transfer factors which are characteristics of the material and not the volume.

Figure 3 – Preparation of mycelium composite samples. (a) Baked P. eryngii brick. (b) Baked P. ostreatus brick. (c) Bricks cut into 2cm thick slices and ready for container assembly.

Figure 4 – Containers manufactured from mycelium and traditionally used materials in different configurations. (a) EPS, configuration 1. (b) EPS70E, configuration 2. (c) P. ostreatus, configuration 1. (d) P. eryngii, configuration 2.

Experimental Set-Up

The experimental set-up used to compare the thermal properties of the materials consisted of a test container including a lightbulb, a power supply, a joule-meter, a digital thermometer, an infra-red (IR) camera and IR thermometer (Fig. 5). An incandescent lightbulb was placed at the bottom of the container on a platform, and the gap between the platform and the wall was insulated with cotton wool to prevent heat loss to the surroundings. The lightbulb was used to heat the air inside; it was connected to a power supply with variable voltage (0-12 V). The supplied electric power was measured by a joule-meter and the temperature was measured by a digital thermometer inserted into the top of the container. IR cameras were used to measure the temperature of the container wall. Before experiments, the temperature readings provided by the IR camera were compared to the temperature measured manually by the thermometer to ensure the accuracy of the measurements.

Figure 5 – Experimental set-up used to conduct all experiments. The apparatus and polystyrene container are used as an example.

The Experiments

Three experiments were designed to compare the performance of two types of mycelia (P. ostreatus and P. eryngii), and two types of polystyrene (EPS and EPS70E). All experiments were conducted in February – March 2023.

Experiment 1 - Heat Capacity

In the first experiment, a 10 V voltage was applied to an incandescent lightbulb placed inside the container, and the time taken for the temperature of the air inside the material containers to reach 40°C was recorded. This was done to qualitatively compare the heat capacity of the material.

Experiment 2 - Thermal Diffusivity

In the second experiment, after heating up to 40°C, the power was adjusted to keep the inside temperature at 40°C until the system reached a steady state with no temperature changes. The temperature of the outside walls was monitored using IR cameras. After that the electric power was switched off, the system was allowed to cool down to room temperature (23°C) and the time taken for the system to cool down was recorded. The experiment was repeated three times for each material and the measured temperature was averaged. This was done to compare the thermal diffusivity properties of the materials.

Experiment 3 - Thermal Conductivity

In the last experiment, the inside air was heated up to three different temperatures of 30°C, 35°C and 40°C until a steady state was reached, and the supplied electric power needed to maintain the constant temperature was measured using a joule-meter. This was done to estimate the thermal conductivity of the materials.

Note that heating and cooling time is dependent on the volume of the material and, therefore, on the volume of the container. When the volume increases, the heating and cooling times also increase. Therefore, the results of each experiment were directly compared only to the results of experiments using the same volume of the container. However, the volume of the container should not affect the heat transfer factors which are characteristics of the material and not the volume.

Results

Experiment 1

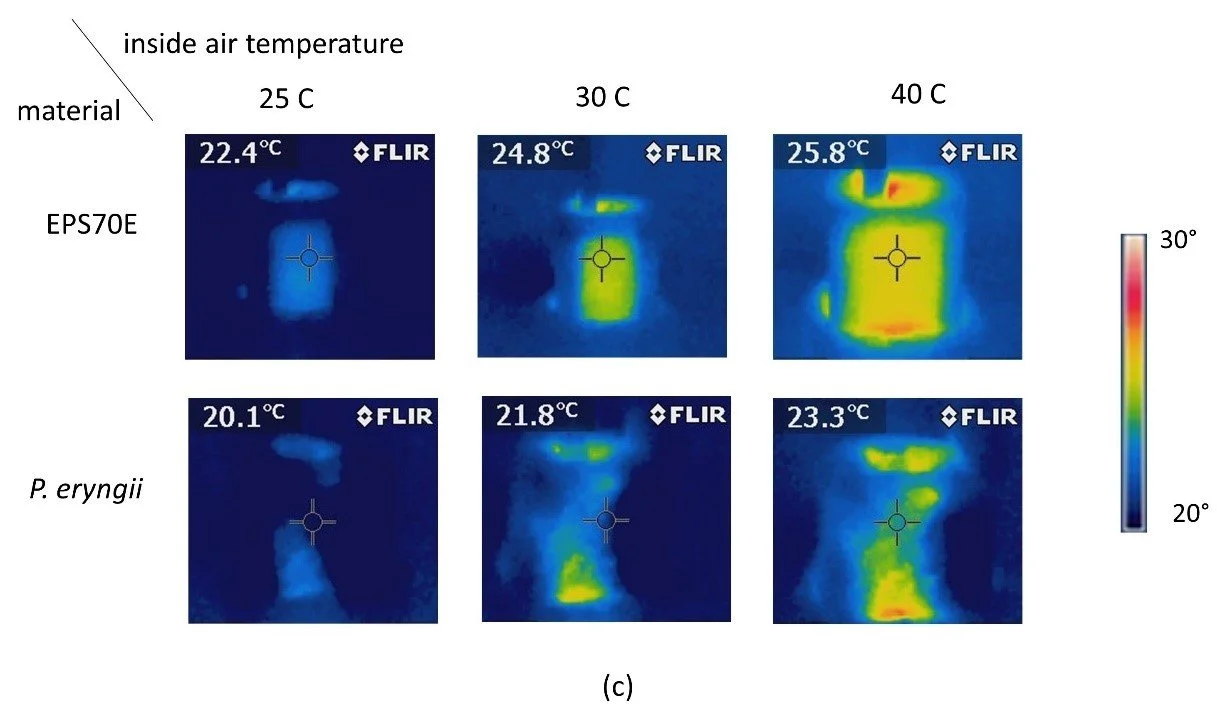

The inside air temperature during the heating-up process was measured; Temperature vs. Time graphs were generated for the two different configurations (Fig. 6(a) and 6(b)), as well as thermal images of the outside wall of the configuration 2 samples (Fig. 6(c)). Results determined that the air inside both mycelium samples took much longer to heat up than in the EPS samples.

Figure 6 – Changes in inside air temperature as a function of time during the heating up process. Applied voltage was 10 V and electric power was 250 W. (a) Temperature vs. Time graph of configuration 1 samples, including P. ostreatus and EPS. (b) Temperature vs. Time graph of configuration 2 samples, including P. eryngii, EPS and EPS70E. (c) Thermal images of the outside wall of EPS70E and P. eryngii samples (configuration 2), showing the temperature distribution at different stages of heating up process.

Experiment 2

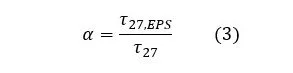

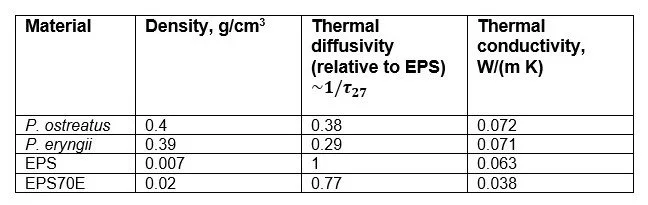

The second experiment allowed for a quantitative comparison of diffusivity properties of the different materials. The decrease of the inside temperature for different materials was measured (Fig. 7). In all experiments the maximum inside temperature was 40°C and room temperature was 23°C. In this case, to measure how quickly the temperature decreased, the time taken for the inside temperature to lower to 27°C was used. This value was chosen as a compromise because the precision of the thermometer (0.1°C) was not enough to reliably measure the inside temperature changes below 27°C. The time required to reach 27°C is shown as τ27. The system diffusivity is approximately proportional to 1/ τ27 (the larger values of τ27 correspond to lower diffusivity). EPS was used as a reference in both experiments (to allow a comparison of results, as τ27 also depends on the geometry of the container). The thermal diffusivity coefficient, α, was calculated relative to this reference using the following equation:

The results showed that the air inside both mycelium samples took around 1000 s to cool down, suggesting they have a higher thermal capacity than both EPS samples, the air in which took 300 – 500 s to cool down on average.

Figure 7 – Inside air temperature during the cooling down process from the steady state at 40 °C. Solid lines correspond to average of three tests (dashed lines). (a) Temperature vs. Time graph of configuration 1 samples, including P. ostreatus and EPS. (b) Temperature vs. Time graph of configuration 2 samples, including P. eryngii, EPS and EPS70E.

Experiment 3

Figure 8 – Thermal conductivity coefficients for mycelium and EPS materials. Calculated for inside air steady-state temperatures of T = 30°C, 35°C and 40°C, and T0 = 23°C. Average values were also determined, showing that the thermal conductivity of mycelium is slightly higher than EPS.

In the third experiment the thermal conductivity coefficient k was calculated using Equation (1). It was assumed that the energy efficiency of the bulb was 10% [27], so 90% of the supplied energy was turning into heat. In this case the electric power, P, was measured by the joule-meter as P = 0.9x. Inside air steady-state temperatures were T = 30°C, 35°C and 40°C, and outside temperature was T0 = 23°C (room temperature). A graph of Thermal conductivity vs. T – T0 was generated to determine the average conductivity of each sample (Fig. 8); thermal images of the outside wall of each sample were also produced (Fig. 9). The thermal conductivity of both mycelium samples was shown to be higher that that of the EPS samples.

A summary of the measured material properties shows that the mycelium samples were more dense, and exhibited lower thermal diffusivity and higher thermal conductivity compared to the EPS samples (Table 3).

Figure 9 – Thermal images of the outside wall of different samples for T = 30°C, 35°C and 40°C. The colour bar at the bottom corresponds to image temperatures between 20°C and 30°C. A lower temperature of the outside wall means that the heat transfer from the container is lower, allowing for qualitative comparison of the thermal conductivities of mycelium and EPS materials.

Table 3 – Summary of the measured material properties, outlining the density, thermal diffusivity and thermal conductivity of each material.

Discussion

In the first experiment, results show that the air inside the mycelium containers takes longer to reach a temperature of 40°C than in polystyrene containers. This could mean two things: most of the heat escapes from the container, or the mycelium walls absorb the majority. However, the thermal images (Fig. 6(b)) show that the outside wall temperatures for mycelium and polystyrene samples are similar, with only one to two degrees difference between samples at each temperature. If most of the heat were leaking from the mycelium container, then the outside wall temperature of the mycelium would be greater. As this is not the case, the longer heating-up time can be explained by the greater thermal capacity of mycelium.

This hypothesis is supported by the results from experiment 2, which show that the mycelium composites display excellent capacity to absorb, store and release heat with thermal diffusivity two to three times lower than EPS. These characteristics make it a good choice for thermal buffering applications. The thermal diffusivity graphs (Fig. 7) can be approximately explained by Newton’s Law of Cooling, according to which the rate of temperature decrease is proportional to the temperature difference between the inside and outside temperatures [28]. The larger this difference, the faster the temperature is decreasing. Mathematically it means that the gradient of the temperature curve (Fig. 7) is approximately proportional to the temperature difference Tin - Tout:

where Tout = 23°C (room temperature) and τ is the time constant. This equation corresponds to the exponential temperature decay [28]:

Figure 10 – Inside air temperature during the cooling process for configuration 1 (Experiment 2). Experimental data (solid lines) and theoretical predictions corresponding to Newton’s Law of cooling (dashed lines) demonstrate good agreement.

The time constant τ can be estimated from Equation (4). A plot of the experimental results for configuration 1 and the theoretical exponential function, Equation (5), demonstrates good agreement (Fig. 10). Note that the rate of the temperature decay is related to thermal diffusivity, which is proportional to 1/τ [25]. On the other hand, the time required to reach any given temperature (T = 27°C in this experiment) is proportional to the constant τ, τ27~τ, and provides a more simple and robust way to estimate the system diffusivity.

According to the results in Experiment 3, the thermal conductivity of mycelium is slightly higher than EPS (Fig. 8); this is supported further by the thermal images (Fig. 9). It can be seen that for each steady state inside temperature value, the EPS70E container has the lowest temperature of the outside wall, meaning that the heat transfer from the EPS70E container is smaller than for other materials. However, the values encountered in this study, which are comparable to values ranging from 0.05 – 0.07 W/mK compiled by K. Alamene et al. [18], are lower than the thermal conductivity of oak wood (0.17 W/mK) [29] which was used as a substrate for the fungi. This shows that the mycelium was responsible for this improvement and can enhance existing properties of materials it is grown in. Note, that the conductivity value of EPS70E (0.038 W/mK) was equal to the value provided by the manufacturer – this proves the good reliability of the experiments.

Overall, in this project, several experiments were performed to compare the thermal insulation properties of mycelium bio-composites and conventional insulation materials. The results of the experiments showed that mycelium has higher thermal conductivity compared to EPS, rendering it less efficient for insulation in colder climates. On the other hand, the mycelium’s excellent thermal buffering properties (high heat capacity and low thermal diffusivity) would be particularly useful for thermal buffering applications, especially in developing countries in Africa and the Middle East with a hot climate: they would ensure the delay in heat transfer through the walls or roof and make it possible to control and prevent overheating of a building. Indeed, proper insulation can reduce the amount of energy used for cooling a building, offering a saving of up to 23.5% compared to a building without insulation, and this energy efficiency is of particular importance to countries with a hot climate [30]. Currently, EPS dominates the Middle East and Africa Building Materials Insulation market with a market share of 53% in 2023 [31]. This shows that there is potential for mycelium to be used commercially in these regions, as it is both cheaper and more efficient than its main alternative, EPS, and so is likely to reduce the EPS market share. Therefore, mycelium insulation would be particularly useful in such countries because of its low production costs, environmental sustainability, and insulation properties. Moreover, although oak pellets were used in this investigation, the mycelium could be grown on a variety of substrates such as excess agricultural waste [32]. This means that this material would not have a negative environmental impact as the substrate would be made of substances that would have otherwise been disposed of, further reducing production costs. Overall, these results reflect our current understanding of this topic and support the results of other studies [10, 14, 17, 18], showing that mycelium is a viable alternative to traditional insulation materials and could be produced with low costs and energy usage in an environmentally friendly manner. However, this investigation is only a preliminary comparison of mycelium insulation to commercially available products (EPS and EPS70E) and is intended to provide the foundation for future work in this area to determine more precise values for this new type of insulation.

In the future, investigations should examine different factors that affect the insulative properties of a fungus. For example, it would be necessary to grow the fungus with a variety of substrates and investigate how this affects its insulative properties, as well as the density of the final product (as in this investigation the mycelium bio-composite was denser than polystyrene). Moreover, it could be beneficial to try using different growth conditions for the fungus. The fungi were grown at room temperature, and whilst this was a convenient solution requiring little temperature control, other temperatures might accelerate fungal growth and should be investigated. Studying this in more detail will enable the optimisation of this new type of insulation. In this investigation, two types of mycelia and polystyrene were used, and further research involving other species and materials is needed to gain a broader understanding of mycelium bio-composites. Moreover, future research could comprise investigating the link between the microstructure of mycelium bio-composites and their thermal properties. Further experimental work is needed to study this new material in more depth, as well as to confirm the findings of this investigation, by accurately measuring the heat transfer factors using standardised equipment and procedures. It is also important to consider other applications of mycelium bio-composites. For example, mycelium could be used for structural support, acoustic insulation, and as a source of chitin and chitosan, which have shown potential for biomedical applications [13].

Acknowledgements

The author would like to acknowledge Bristol Grammar School for providing equipment for conducting experiments.

Author's Notes

All figures, or tables, were created by the Author, unless otherwise mentioned in the description provided of said figure.

Definitions of Key Terms

Basidiomycete - A member of the Basidiomycota phylum of fungi

Bio-composite - A material composed of two or more distinct constituent materials (one being naturally derived) which are combined to yield a new material with improved performance over individual constituent materials

Hydrated - Having absorbed water

Latex - A natural material derived from rubber trees

Microfibrils - A microtubule, microfilament, or other fine threadlike structure of a cell

Newton’s Law of Cooling - The rate of heat loss of a body is directly proportional to the difference in the temperatures between the body and its environment

Pasteurisation - Partial sterilisation, aimed at eliminating the majority of microorganisms

(Wood) Pellets - A compressed form of woody biomass used as an eco-friendly, low carbon alternative to traditional fossil fuels

Radical - A molecule that contains at least one unpaired electron

Spawn - A substrate that already has mycelium growing on it, used for propagating mycelium to new bulk substrates

Substrate - Material which the fungus can digest and use for energy while it grows

Thermal Buffering - Delay in heat transfer through the material

References

[1] L. Aditya et al., “A review on insulation materials for energy conservation in buildings,” Renewable and Sustainable Energy Reviews, vol. 73, pp. 1352-1356, 2017. Available: https://doi.org/10.1016/j.rser.2017.02.034.

[2] UK Climate Change Committee, “The Sixth Carbon Budget,” 2020. [Online]. Available: https://www.theccc.org.uk/wp-content/uploads/2020/12/The-Sixth-Carbon-Budget-The-UKs-path-to-Net-Zero.pdf. [Accessed 20 February 2025].

[3] D. Kumar, M. Alam, P. X. W. Zou, J. G. Sanjayan and R. A. Memon, “Comparative analysis of building insulation material properties and performance,” Renewable and Sustainable Energy Reviews, vol. 131, 2020. Available: https://doi.org/10.1016/j.rser.2020.110038.

[4] Buy Insulation Online, “Facts About Expanded Polystyrene Insulation,” Buy Insulation Online. [Online]. Available: https://www.buyinsulationonline.co.uk/blog/facts-about-expanded-polystyrene-insulation. [Accessed 19 February 2024].

[5] S. Bidwai, “Building Thermal Insulation Market,” Precedence Research, November 12, 2024. [Online]. Available: https://www.precedenceresearch.com/building-thermal-insulation-market#:~:text=The%20global%20building%20thermal%20insulation,forecast%20period%202023%20and%202032. [Accessed 20 February 2025].

[6] I. M. Maafa, “Pyrolysis of Polystyrene Waste: A Review,” Polymers, vol. 13, no. 2, 2021. Available: https://doi.org/10.3390%2Fpolym13020225.

[7] National Toxicology Program, “15th Report on Carcinogens,” 2021. [Online]. Available: https://ntp.niehs.nih.gov/research/assessments/cancer/roc. [Accessed 2 July 2025].

[8] C. V. Vo and R. T. Fox, “Assessment of hydrofluoropropenes as insulating blowing agents for extruded polystyrene foams,” Journal of Cellular Plastics, vol. 49, no. 5, pp. 423-438, 2013. Available: https://doi.org/10.1177/0021955X13488398.

[9] United States Environmental Protection Agency, “Greenhouse Gas (GHG) Emissions and Removals”, EPA, December 20, 2024. [Online]. Available: https://www.epa.gov/ghgemissions. [Accessed 20 February 2025].

[10] L. Yang, D. Park and Z. Qin, “Material Function of Mycelium-Based Bio-Composite: A Review,” Frontiers in Materials, vol. 8, 2021. Available: https://doi.org/10.3389/fmats.2021.737377.

[11] D. Arora, Mushrooms Demystified: A Comprehensive Guide to the Fleshy Fungi, Berkeley: Ten Speed Press, 1986.

[12] T. Ghosh, “Developing a Composite Mycelium-Glass Brick Unit,” 2018. [Online]. Available: https://core.ac.uk/download/pdf/275765978.pdf. [Accessed 4 June 2023].

[13] M. D. Lenardon, C. A. Munro, N. AR Gow, “Chitin synthesis and fungal pathogenesis,” Current Opinion in Microbiology, vol. 13, no. 4, pp. 416-423, 2010. Available: https://doi.org/10.1016/j.mib.2010.05.002.

[14] D. Alemu, M. Tafesse and A. K. Mondal, “Mycelium-Based Composite: The Future Sustainable Biomaterial,” International Journal of Biomaterials, vol. 2022, 2022. Available: https://doi.org/10.1155%2F2022%2F8401528.

[15] M. Jones et al., “Thermal Degradation and Fire Properties of Fungal Mycelium and Mycelium - Biomass Composite Materials”, Scientific Reports, vol. 8, 2018. Available: https://doi.org/10.1038%2Fs41598-018-36032-9.

[16] V. Meyer et al., “Growing a circular economy with fungal biotechnology: a white paper,” Fungal Biology and Biotechnology, vol. 7, pp. 1-23, 2020. Available: https://doi.org/10.1186%2Fs40694-020-00095-z.

[17] S. Al-Qahtani, M. Koç and R. J. Isaifan, “Mycelium-Based Thermal Insulation for Domestic Cooling Footprint Reduction: A Review,” Sustainability, vol. 15, no. 17, 2023. Available: https://doi.org/10.3390/su151713217.

[18] K. K. Alaneme et al., “Mycelium based composites: A review of their bio-fabrication procedures, material properties and potential for green building and construction applications,” Alexandria Engineering Journal, vol. 83, pp. 234-250, 2023. Available: https://doi.org/10.1016/j.aej.2023.10.012.

[19] R. Rathinamoorthy, T. S. Bharathi, M. Snehaa and C. Swetha, “Mycelium as sustainable textile material – review on recent research and future prospective,” International Journal of Clothing Science and Technology, vol. 35, no. 3, pp. 454 – 476. Available: https://doi.org/10.1108/IJCST-01-2022-0003.

[20] Greenspec, “Insulation materials and their thermal properties,” Greenspec. [Online]. Available: https://www.greenspec.co.uk/building-design/insulation-materials-thermal-properties/.[Accessed 4 June 2023].

[21] A. Livne, H. A. B. Wösten, D. Pearlmutter and E. Gal, “Fungal Mycelium Bio-Composite Acts as a CO2-Sink Building Material with Low Embodied Energy”, ACS Sustainable Chemistry and Engineering, vol. 10, no. 37, pp. 12099-12106, 2022. Available: https://doi.org/10.1021/acssuschemeng.2c01314.

[22] M. Wu, J. McIntosh and J. Liu, “Current prevalence rate of latex allergy: Why it remains a problem?,” Journal of Occupational Health, vol. 52, no. 2, pp. 138-144, 2016. Available: https://doi.org/10.1539%2Fjoh.15-0275-RA.

[23] T. Pullen, “Wood Fibre Insulation: What are the Pros and Cons,” Homebuilding & Renovating, November 19, 2019. [Online]. Available: https://www.homebuilding.co.uk/advice/wood-fibre-insulation. [Accessed 19 February 2024].

[24] Critical Concrete, “Mycelium Cardboard Insulation,” Critical Concrete, January 31, 2019. [Online]. Available: https://criticalconcrete.com/mycelium-cardboard-insulation/. [Accessed 19 February 2024].

[25] Greenspec, “Decrement delay & Thermal buffering,” Greenspec. [Online]. Available: https://www.greenspec.co.uk/building-design/decrement-delay/. [Accessed 4 June 2023].

[26] A. Sayner, “How to Sterilize Mushroom Substrate: A Step-by-Step Guide,” GroCycle. [Online]. Available: https://grocycle.com/how-to-sterilize-mushroom-substrate/#:~:text=You'll%20need%20to%20sterilize%20high%20nutrient%20substrates%20or%20substrates,and%20cardboard%20only%20need%20pasteurization. [Accessed 4 June 2023].

[27] GE Lighting, “A Guide to Energy Efficient Lightbulbs,” GE Lighting, November 10, 2022. [Online]. Available: https://www.gelighting.com/inform/guide-energy-efficient-light-bulbs. [Accessed 7 July 2023].

[28] R. H. S. Winterton, “Newton’s Law of Cooling,” Contemporary Physics, vol. 40, no. 3, pp. 205-212, 1999. Available: https://doi.org/10.1080/001075199181549.

[29] Material-properties.org, “Oak Wood – Density – Strength – Melting Point – Thermal Conductivity,” Material-properties.org. [Online]. Available: https://material-properties.org/oak-wood-density-strength-melting-point-thermal-conductivity/. [Accessed 4 June 2023].

[30] Z. Fang, N. Li, B. Li, G. Lou and Y. Huang, “The effect of building envelope insulation on cooling energy consumption in the summer,” Energy and Buildings, vol. 77, pp. 197 – 205, 2014. Available: https://doi.org/10.1016/j.enbuild.2014.03.030.

[31] Stellar Market Research, “Middle East & Africa Building Insulation Materials Market: Industry Analysis and Forecast (2024-2030),” Stellar Market Research, July 13, 2023. [Online]. Available: https://www.stellarmr.com/report/MEA-Building-Insulation-Materials-Market/1264#:~:text=Extruded%20Polystyrene%20has%20the%20market,expected%20to%20help%20with%20growth. [Accessed 20 February 2024].

[32] R. Cohen and Y. Hadar, “The roles of fungi in agricultural waste conversion," Fungi in Bioremediation, vol. 23, pp. 305-334, 2001. Available: https://doi.org/10.1017/CBO9780511541780.012.

About This Article

Peer review information: Primary Handling Research Editor: Luna Ramírez. Coordinating Research Editor: Elizabeth Bourn. Youth STEM Matters thanks Josh Heng, Emmanuel Randle, Isabelle Johnson, Ronald Kamahaa and Mariana Mastache-Maldonado for their contribution to the peer review of this work.

Received: 3 July 2023

Accepted: 11 November 2024

Published: 6 August 2025